🧪 Research Areas

- High-Entropy Materials and Complex Concentrated Alloys

- Phonon Transport and Thermal Management

- Alloy Design for Extreme Environments

- Functional Materials

My work aims to accelerate the discovery of materials that perform reliably under extreme conditions, advancing technologies in clean energy, aerospace, and national security.

Research Directions

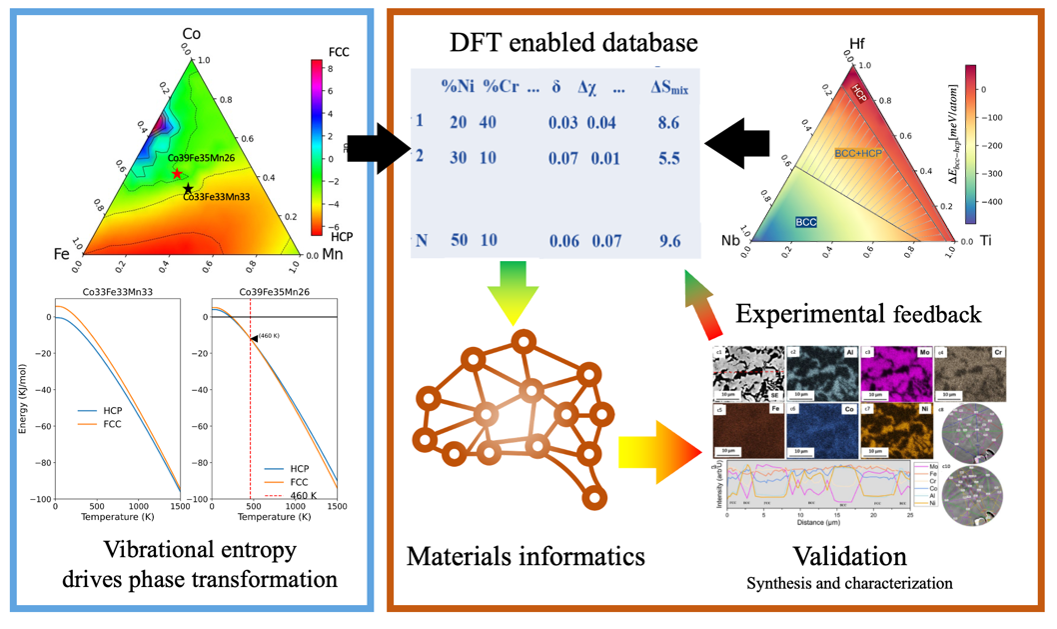

Controlling Phase Transformation and High Throughput Exploration

In phase transformation of alloys, understanding and manipulating the competition between different crystal structures is important. Our research exploits DFT-based energetics calculations to study systems like CoFeMn. These calculations reveal how vibrational entropy can stabilize the FCC structure over HCP. Additionally, we use machine learning models to design high-entropy alloys/materials with superior structural and desired physical properties. By integrating computational and data-driven approaches we can predict and optimize the material properties. This significantly accelerates the discovery and development process.

Highlights:

- Revealed competition between crystal structures in alloys.

- Demonstrated vibrational entropy's role in stabilizing structures.

- Designed alloys with superior hardness using machine learning.

- Accelerated material discovery for industrial applications.

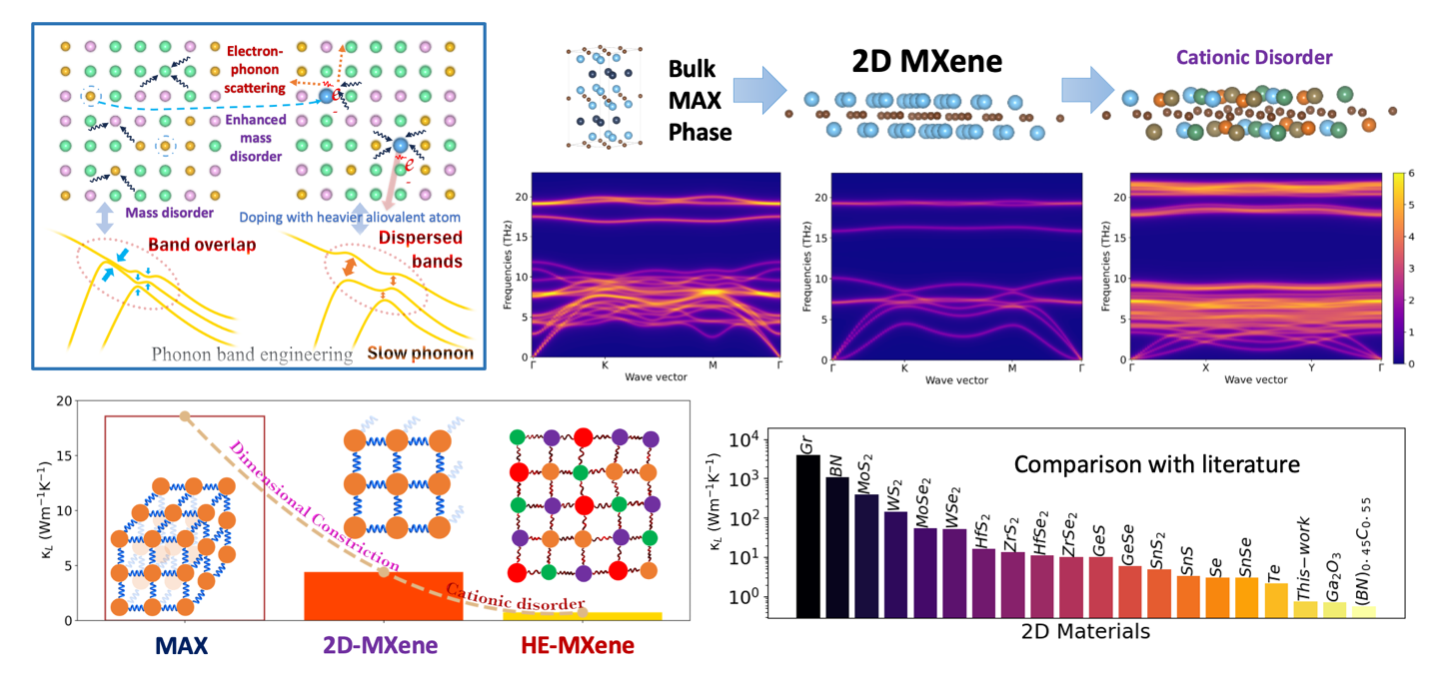

Phonon Engineering for Thermal Conductivity in Extreme Environments

Material composition alterations influence phonon dynamics to control thermal conductivity, targeting materials like MAX phases and MXenes for extreme conditions in aerospace and energy systems. Our work mainly focuses on the crystal structures of various materials, such as the Ti₂AlC MAX phase, dimensionally constricted Ti₂C monolayers, and high-entropy MXenes like (Ti₀.₂₅Nb₀.₂₅Cr₀.₂₅Ta₀.₂₅)₂C. We reveal the significant effects of cationic disorder on thermal properties.

Highlights:

- Demonstrated material substitution's impact on phonon behavior.

- Investigated specific materials for thermal management.

- Proved structural changes affect thermal conductivity.

- Enhanced thermal properties for harsh environments.

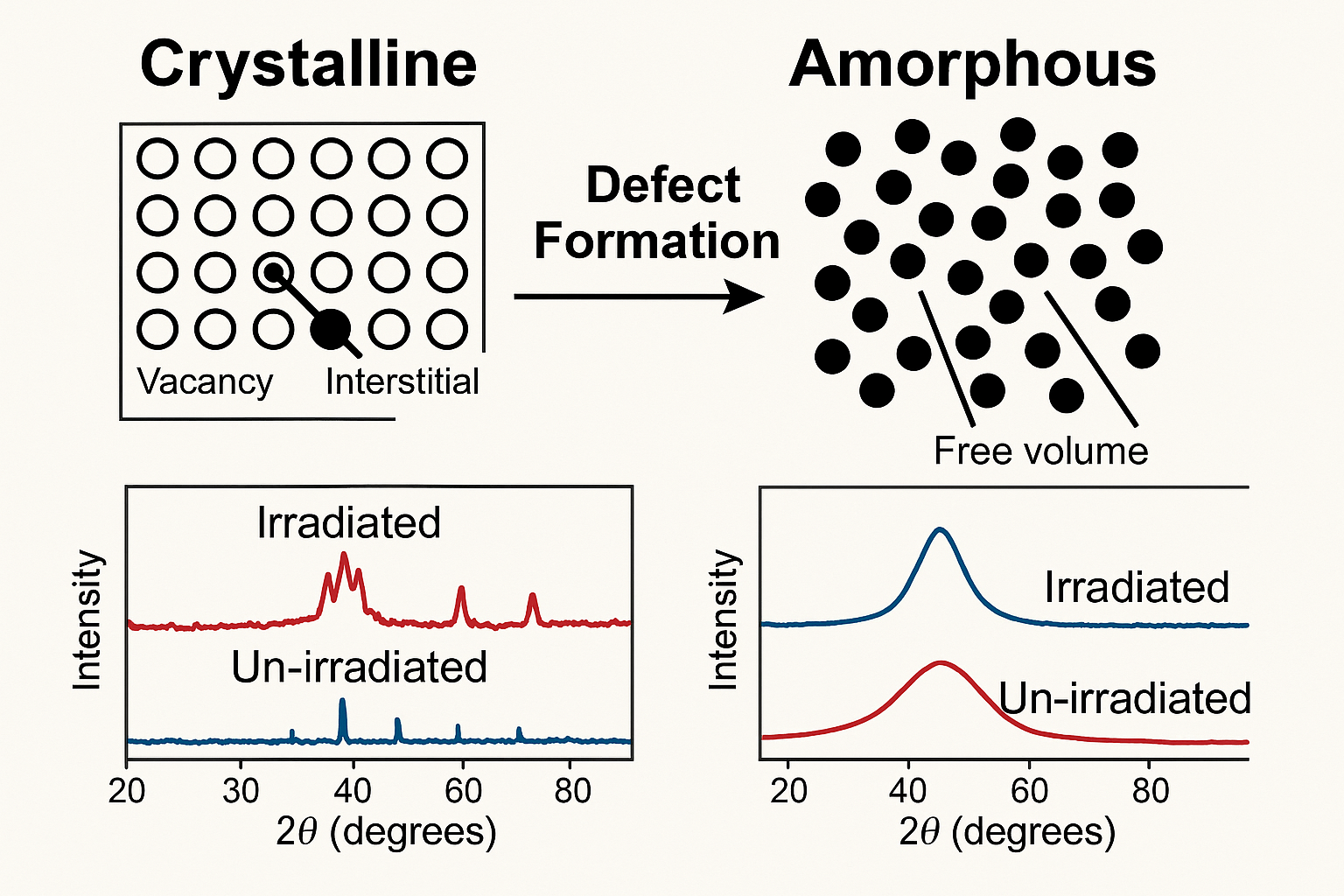

High-Throughput Discovery of Radiation-Resistant Amorphous Materials

Amorphous materials with high radiation resistance for nuclear applications are developed using density functional theory, machine learning, and experimental validation to ensure stability under extreme conditions. The fundamental mechanisms of defect formation in crystalline versus amorphous materials, and compares structural responses to irradiation. While crystalline materials exhibit defect accumulation and phase changes, amorphous materials tend to retain their disordered structure, as confirmed by diffraction analysis showing the absence of long-range order even after high-dose irradiation.

Highlights:

- Confirmed amorphous materials' superior radiation tolerance.

- Outperformed crystalline materials under irradiation.

- Maintained structural stability under high radiation doses.

- Advanced material discovery for nuclear energy applications.

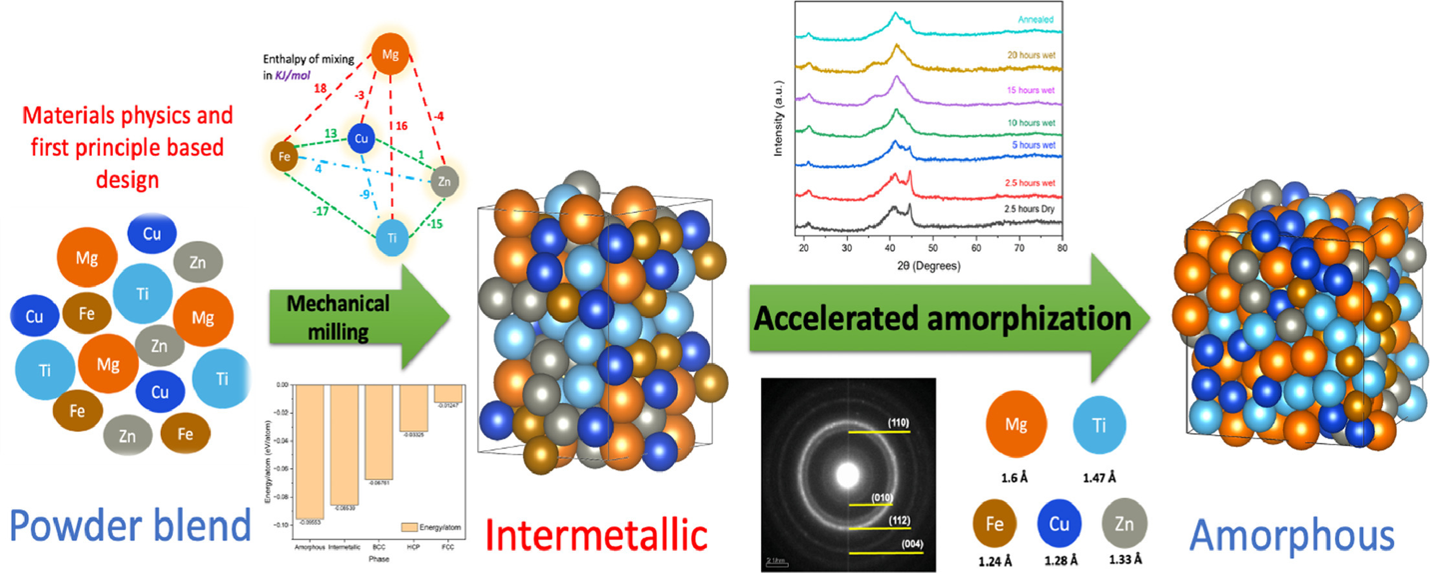

Ultrafast Synthesis of Amorphous Powders

Specialized powders, such as magnesium-titanium-based high-entropy alloys, are developed for additive manufacturing, improving stability and performance for hydrogen storage, biomedical, and aerospace applications.

Highlights:

- Produced amorphous powders through mechanical milling.

- Improved stability and corrosion resistance.

- Enabled applications in high-demand industries.

- Enhanced manufacturing processes for lightweight components.

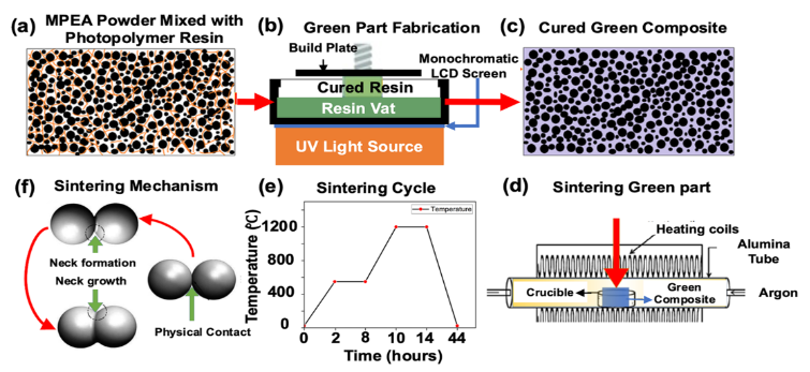

Innovative Additive Manufacturing Techniques for High-Entropy Alloys

A novel process combining thermal solvent extraction with stereolithography manufactures high-entropy alloy components, creating porous structures with high hardness and low density for advanced applications.

Highlights:

- Developed a novel manufacturing process for alloys.

- Achieved high hardness and low density in components.

- Provided cost-effective and scalable production methods.

- Improved control over microstructural features.